Here we will focus on several characteristics of the plate to see how they interact to assist the CTP equipment for digital plate making, thus affecting the image quality. This applies to all CTP plates, but is particularly suitable for thermal plates. At present, the global use of thermal plates has increased dramatically and has been recognized as the preferred medium for high-quality lithography.

Requirements for aluminum base

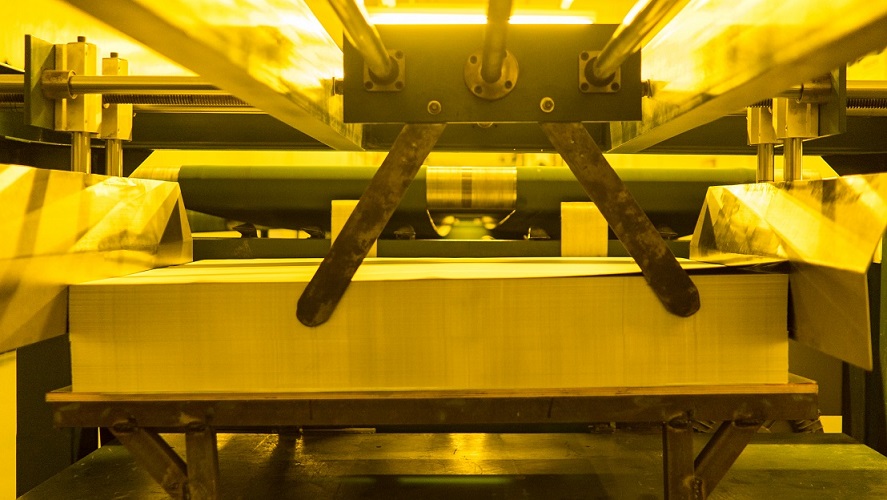

In traditional platemaking, whether or not a dot can be accurately positioned on a plate material depends to a great extent on whether the position of the imposition and registration register device is accurate when using a vacuum pump or a continuous copy device. In any case, this requires the plate to be quite flat when laid flat, but since the imaging process uses direct-contact exposure, the entire process can accept variations in the flatness of various types of plates, and the flatness of these surfaces is changed by Aluminium-based surface treatment caused by the production of traditional media. However, because digital printing plates are exposed by focusing energy from a laser light source, the requirements for the flatness of digital media include stricter treatment of aluminum-based surfaces.

In addition, the use of energy-focused imaging in contrast to direct imaging means that no visible streaks will be visible when imaging on digital plates because no streaks will occur during anodization and graining of aluminum plates.

Coating

When applied to digital plates, emulsions must be smooth, uniform, and free of defects. Because the dot size generated on a laser platemaking machine is very small, any dust in the air during the production process of the reel, no matter how small, falls on the plate material, will lead to this personal image point. In fact, irregular images due to static spots are also visible, and they are very small and can't even be seen by a magnifier that checks traditional printing plates.

The same uniformity requirement is also applied in the photosensitive coating of digital printing plate material. In general, when a traditional printing plate is exposed to ultraviolet light, the energy it receives is approximately 10,000 times the energy transmitted from the laser system to the digital printing plate coating in the direct plate making equipment. This means that in order to accurately meet the physical properties mentioned above, the emulsion coating of digital printing plates must be very stringent to achieve a specific range of spectral sensitization characteristics, satisfying synthetic materials (especially the molecular architecture in the coating), And the energy reaction is active. As a result, factories that produce digital printing plates require special, additional chemicals, and also require special production workflows.

Operational requirements

Compared with traditional media, CTP media also require different modes of operation during handling. Because many digital media imaging uses the edge of the plate as the key reference point for calculating the imaging position. Digital media has very strict requirements on the degree of edge straightness and evenness. Although this is only a minor issue for traditional media, if the edge of the digital media is not straight, unusual or damaged, the media will not work properly.

service

The final step in digital media production is to create and maintain a service team that can help printers solve problems anytime anywhere. This is a question that should be considered when evaluating any traditional and digital media, but it is especially important for digital media. Because printers that generally use CTP production are due to customers having a particularly strict time limit, this means that if problems arise, they must be resolved immediately.

to sum up

When comparing different digital plates or platemaking systems, it is worth noting that the final product is not a stack of plates sent to the pressroom, but rather printed by a faultless printing of precisely imaged plates on the press. Products.

When considering the cost of producing digital plates, consider several important factors that have higher costs than traditional plates. The most important point is the demand for high quality raw materials. Thermal technology is the preferred technology for printers using CTP systems. Thermal plates will provide users with accurate quality and stable high quality.